Reduction of time and costs with advanced analysis techniques

in order to obtain the best performance / weight ratio while maintaining the reliability of the structure at the same time.

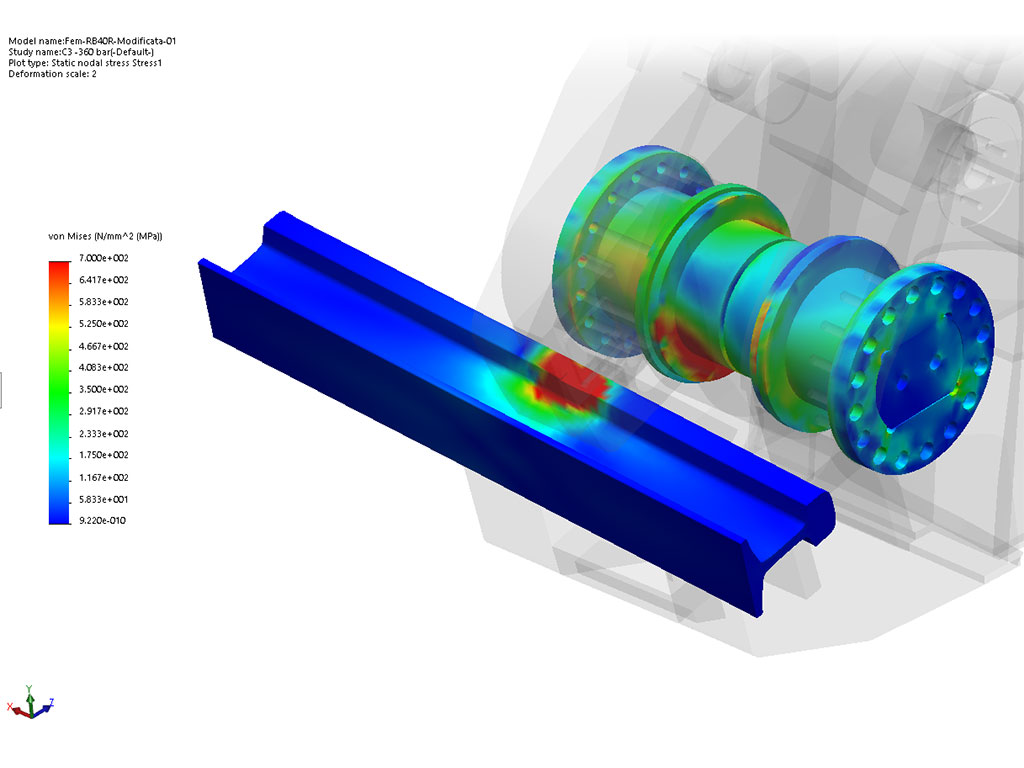

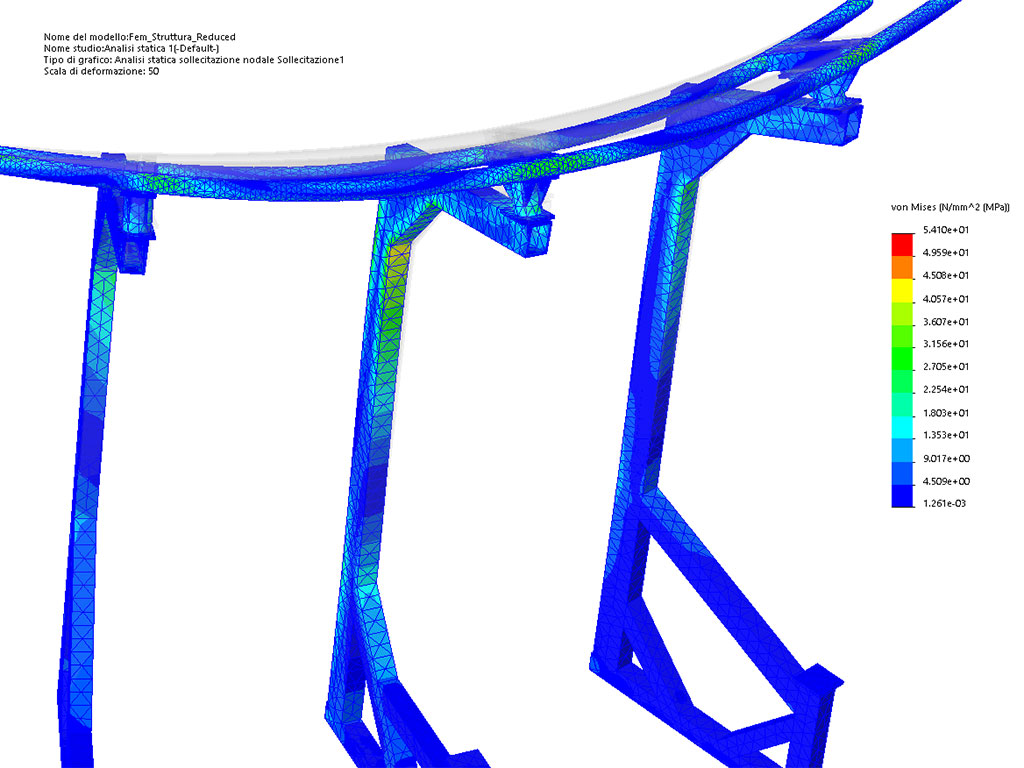

Structural Analyses

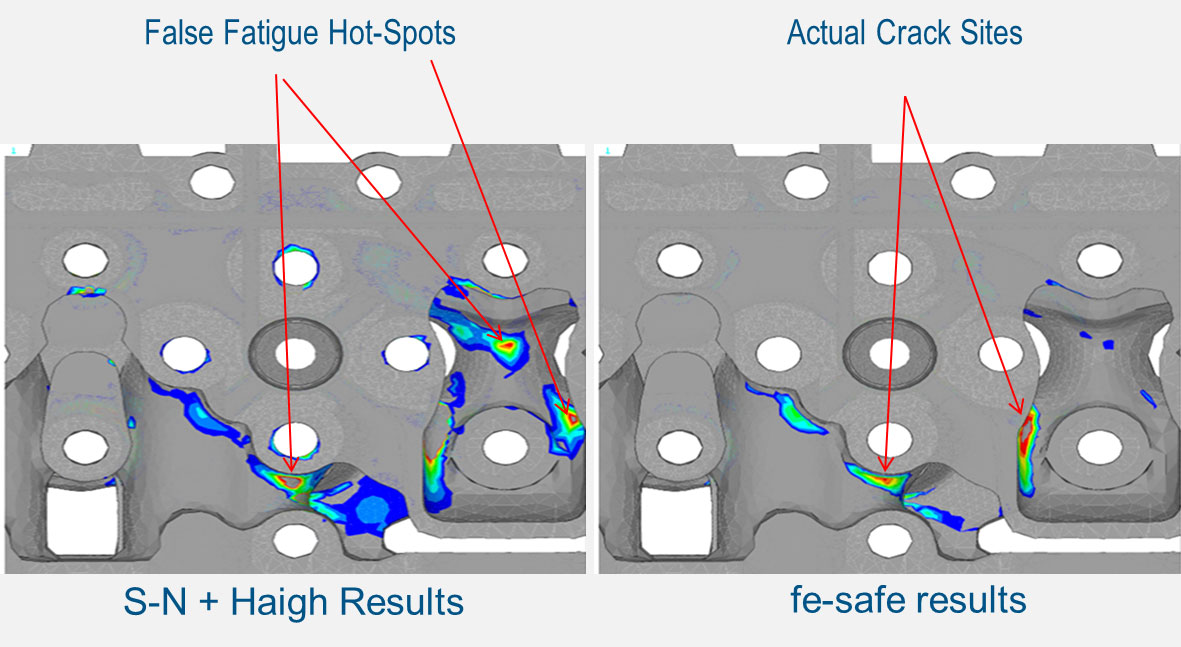

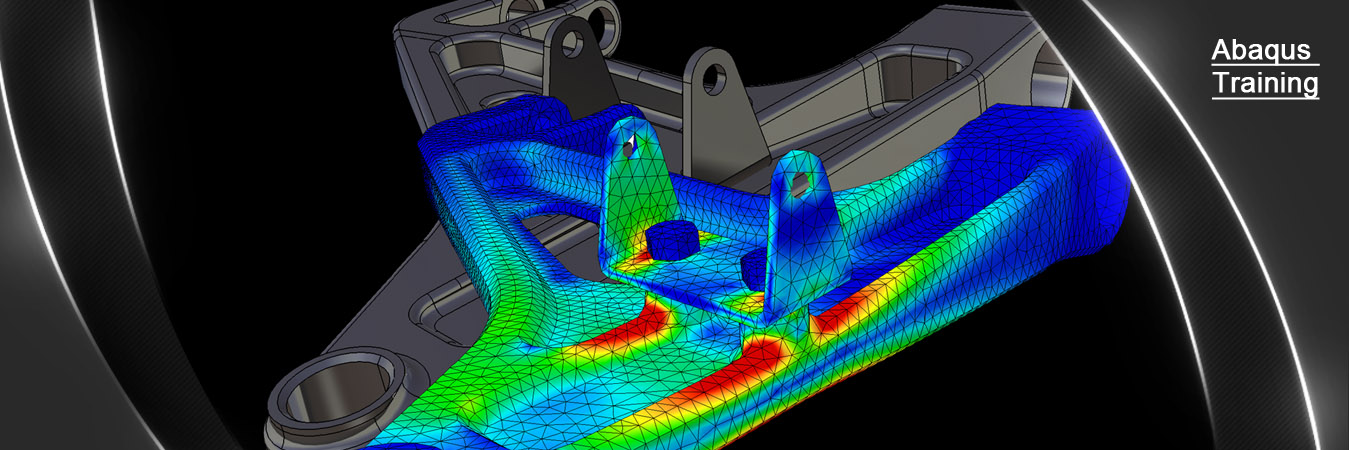

We use software approved by NAFEMS and therefore with high quality and reliability standards:

The software we use for these types of analyzes include

ABAQUS, Fe-Safe, Isight, Solidworks Simulation, MSC Patran and MSC Apex.

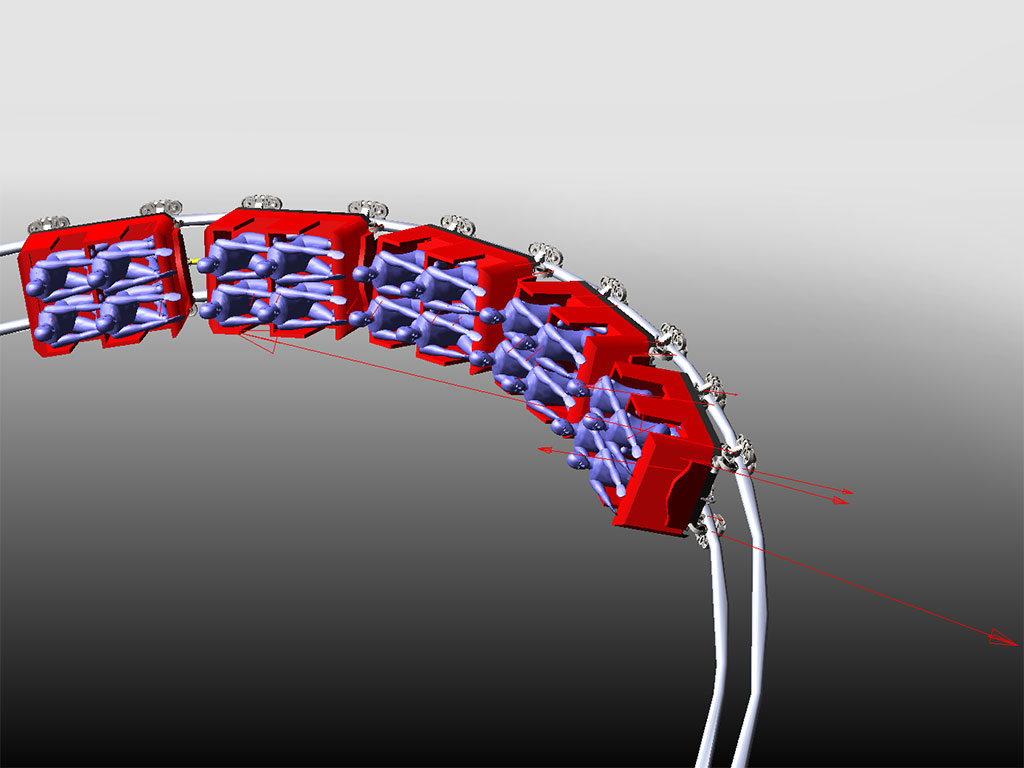

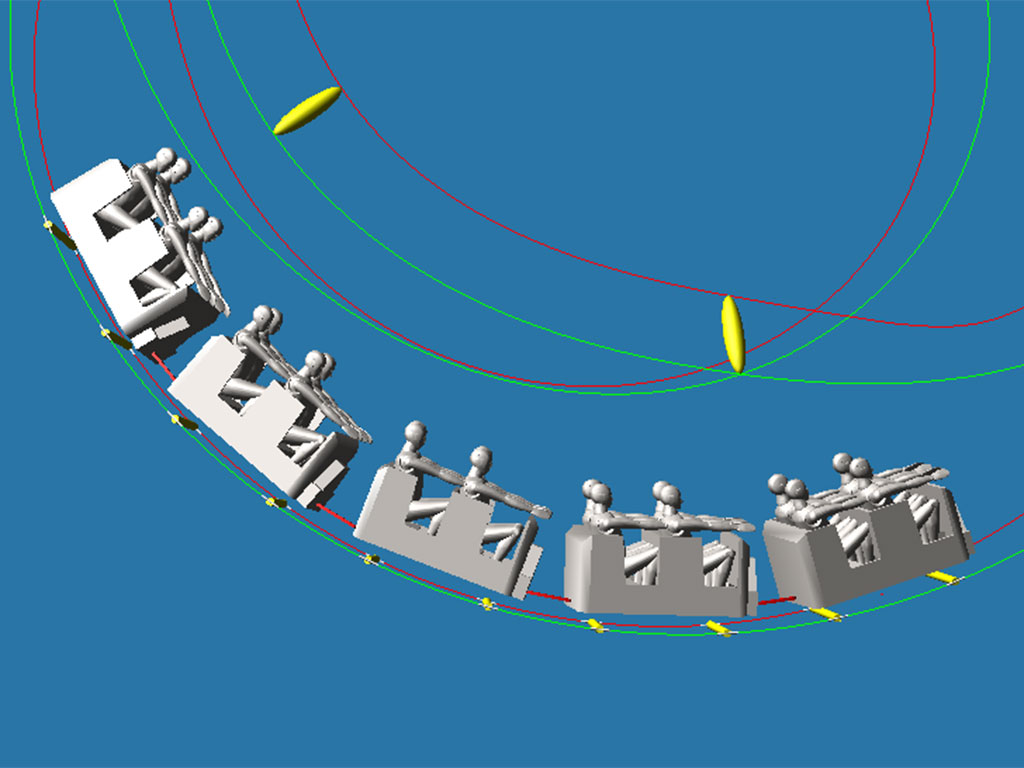

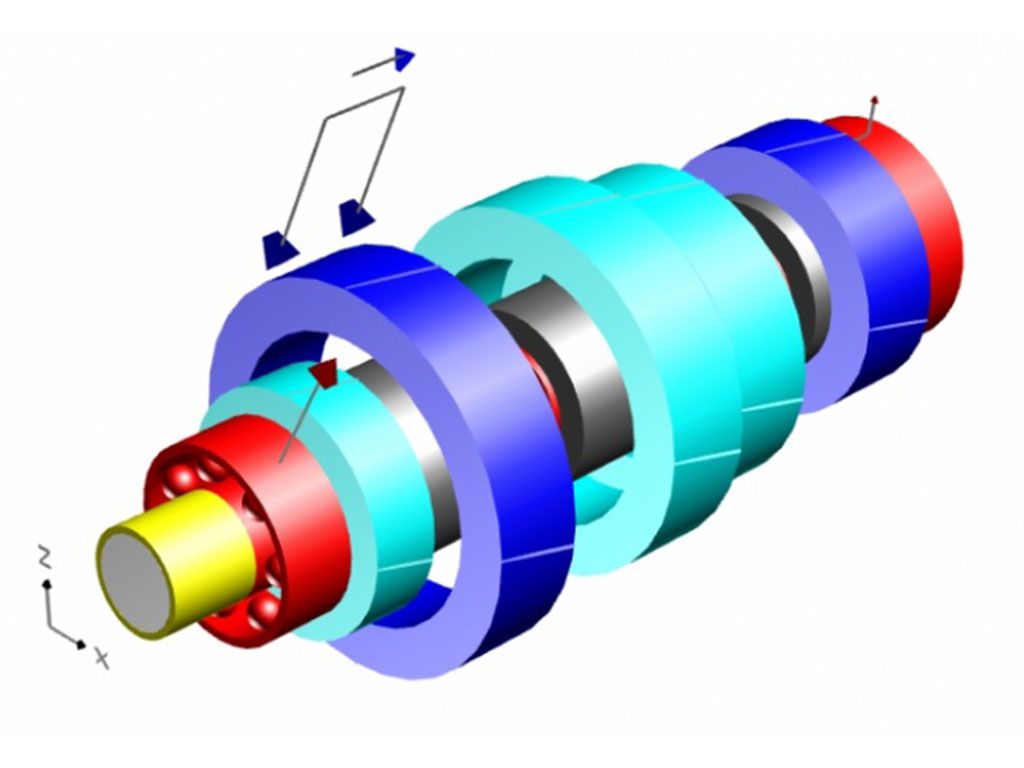

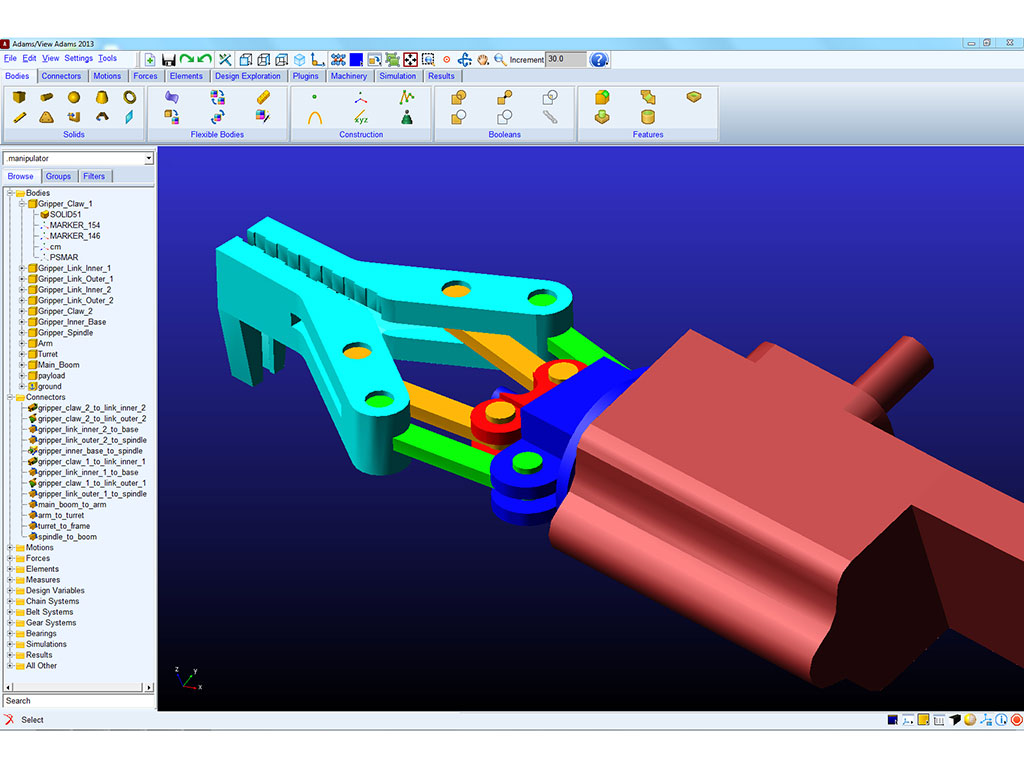

Kineto dynamic analyses

Kineto dynamic analyses are essential in applications with multiple kinematics

where accelerations and inertia constitute essential aspects of the analysis or when the movement and forces involved must be obtained considering the interaction of multiple degrees of freedom between them.

For this work we rely on MSC ADAMS and customer-made software of VI-Grade.

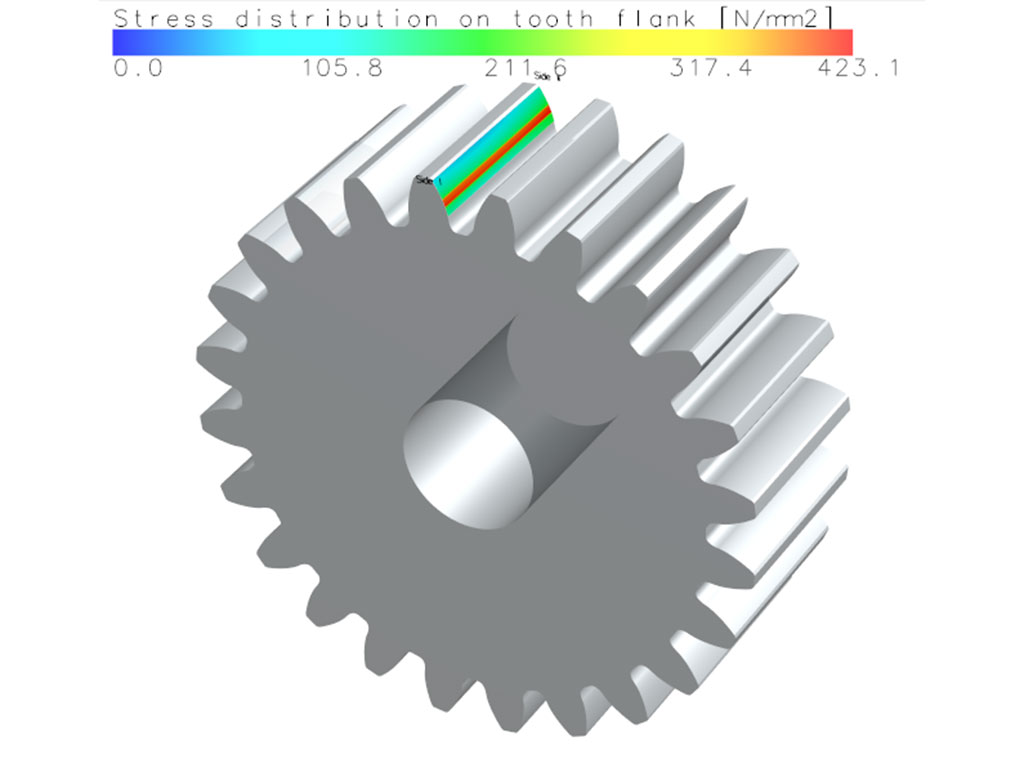

Dedicated analysis for cycloidal kinematics

The analysis of gears and shafts is carried out using the dedicated Kisssoft program.

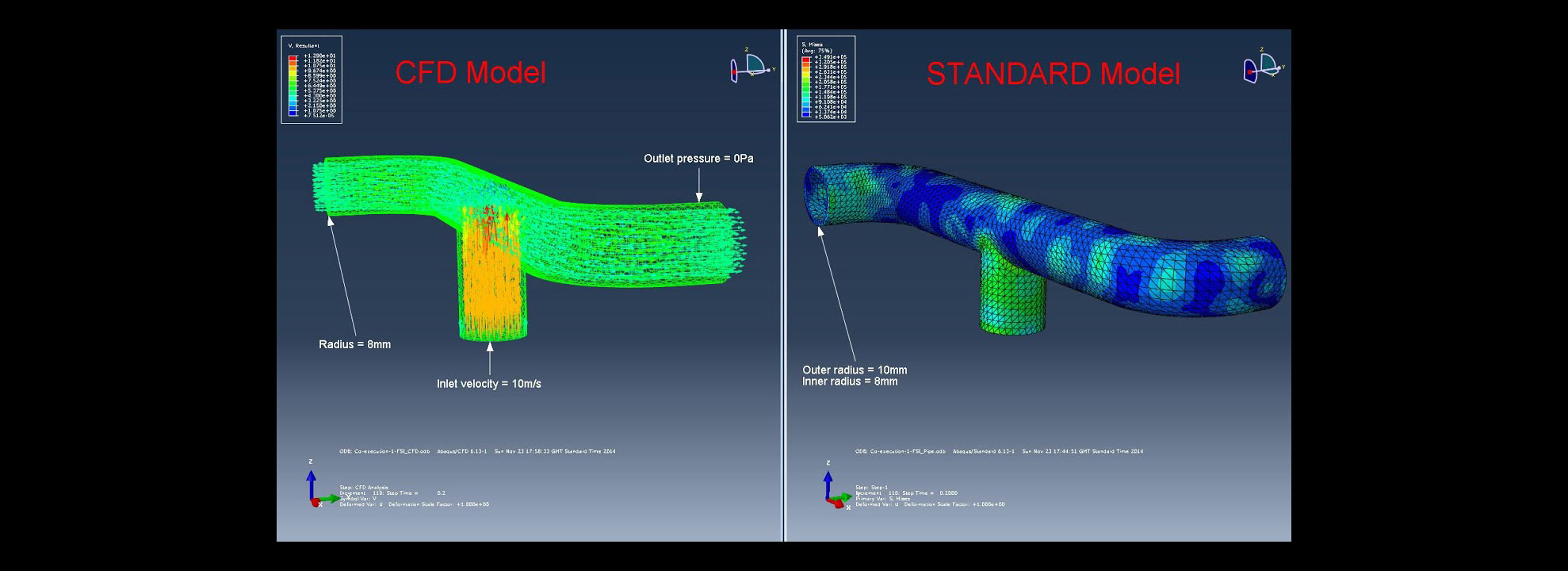

Fluid dynamic analyses CFD

Fluid dynamic analyses are performed with dedicated software for the various sectors that require the possibility.

Development of Costruction Drawing and Technical Document

Solidworks and Inventor are the software used for the creation of Construction drawing in order to provide the complete design package if required:

Technical Feasibility

Technical feasibility study aimed at evaluating new ideas and products, technological and design features and possibilities, carried out before proceeding with the technical design.

In this phase, a creative method is fundamental, oriented towards problem solving and close collaboration with the company/client, without which it would be impossible to analyze the expectations and knowledge that customers have of the product / service and to transform them into innovative products / services.

Dual Scope:

• identify those technical, functional and aesthetic characteristics capable of responding positively to customer needs and ideas;

• perform a first orientation analysis of needs: indicative estimate of the investment and development cost of the project in terms of human and material resources, timing and any return on investment.

Upon customer request, this phase may include an initial patent analysis or technical training sessions for its innovation staff.

- Standard Functions and Contents;

- Define the innovative idea and its objectives;

- Analyses the technical feasibility and market attractiveness of the project;

- Make a first estimate of the investments and costs of the product;

- Better understand the characteristics of the target market.

Risk Assessment

To demonstrate to the customer the compliance of his machine with the Directive, the Manufacturer must draw up the Technical File of the construction

which must contain, among other documents (Annex V – paragraph 3 a), a description of the solutions adopted to prevent the risks presented from the car. This is precisely the main reason for the Risk Analysis. The manufacturer must select the risks possibly presented by a machine and try to eliminate them.

The Machinery Directive (Annex I) contains the Essential Requirements, each of which concerns a possible risk linked to the operation of the machine:

a machine must be comply with all applicable requirements. If this does not happen, the machine presents a risk for the operator and exposed people.

Industrial design

Integrated Design

The services offered are varied and include:

• Preliminary feasibility analysis of the attraction;

• Reverse Engineering or complete and integrated mechanical, structural and electrical design of the attraction with analysis and drafting of tables according to the Regulations;

• Drafting of the documentation according to the standard (risk analysis, log book, manuals, technical drawings and wiring diagrams, performance level analysis) already during the design, significantly shortening waiting times;

• NDT checks on welds;

• Qualification of suppliers;

• Optimization of technical solutions;

• PLC programming;

• Software validation.